企业:深圳市中科恒润科技发展有限公司

联系人:张经理

电话:0755-33129116/27460211

手机:13632638605

传真:0755-29939126

网址:www.szonrun.com

地址:深圳市宝安区沙井新桥第三工业区金元四路13号

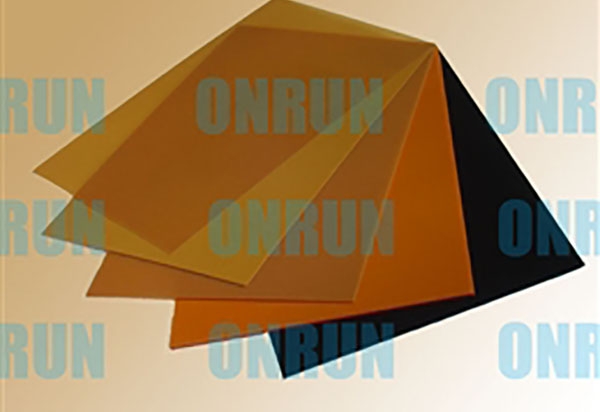

FR4环氧板的加工方法

FR4有其他的名称:包括FR-4光学板、FR-4纤维板、FR-4环氧树脂板和FR-4阻燃绝缘板。这些标题也从侧面反映了FR-4玻璃纤维板的广泛应用。FR-4玻璃纤维板通常用于软包装基层,然后将布和皮革包裹在外面,使墙壁和天花板装饰美观。它被广泛使用。它具有吸声、隔音、隔热、环保、阻燃等特点。以下是FR-4玻璃纤维板的具体性能特点分析:FR-4环氧玻璃纤维布是以环氧树脂为粘合剂,电子玻璃纤维布为增强材料的基材。其粘合片和内芯薄覆铜板是制造多层印制电路板的重要基材。

There are many other names, including FR-4 light sheet, FR-4 fiber sheet, FR-4 epoxy sheet, FR-4 flame retardant sheet, so many names also reflect the wide application of FR-4 fiberglass sheet from other side. . FR-4 fiberglass sheet is generally used for soft-packing base layer, and then wrapped with fabric, leather, etc., to make beautiful wall and ceiling decoration. The application is very extensive. With sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and so on. The following is a detailed analysis of the performance characteristics of FR-4 glass fiberglass sheet: FR-4 epoxy fiberglass cloth, which is a kind of substrate with epoxy resin as binder and electronic grade glass fiber cloth as reinforcing material. Its bonding sheet and inner core thin copper clad plate are important substrates for making multilayer printed circuit boards.

性能:环氧玻璃纤维布基材的力学性能、尺寸稳定性、耐冲击性和防潮性均高于纸基材。其电气性能优良,工作温度高,受环境影响小。在加工工艺上,它比其他树脂的玻璃纤维布基板有很大的优势。这类产品主要用于双面PCB,数量较多。电气绝缘性能稳定,平整度好,表面光滑,无凹坑,厚度公差标准,适用于FPC加强板、PCB钻垫、玻璃纤维介子、电位器碳膜印制玻璃纤维板等具有高性能电子绝缘要求的产品,精密行星齿轮(硅片研磨)、精密试验板、燃气(电器)设备绝缘支撑隔板、绝缘垫板、变压器绝缘板、电机绝缘、研磨齿轮、电子开关绝缘板等。

Performance: The mechanical properties, dimensional stability, impact resistance and moisture resistance of the epoxy fiberglass substrate are higher than those of the paper substrate. Its electrical performance is excellent, its operating temperature is high, and its performance is less affected by the environment. In terms of processing technology, it has great advantages over other resin fiberglass cloth substrates. These products are mainly used for double-sided PCBs and are used in large quantities. Stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for high performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon Film printing fiberglass board, precision star gear (wafer grinding), precision test board, gas (electrical) equipment insulation struts, insulation pads, transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation boards, etc.

FR-4环氧板压板加工的表面处理

1.在对铜表面进行图形化和蚀刻以形成电路后,应尽量减少处理和与PTFE表面的接触。操作员应戴上干净的手套,并在每块板上涂一层薄膜,以便转移到下一工序。

After the copper surface is patterned and etched to form a circuit, try to reduce the handling and contact of the PTFE surface. The operator should wear clean gloves and place a film on each board for transfer to the next procedure.2.蚀刻PTFE表面具有足够的粗糙度,可用于粘接。如果要粘合蚀刻板或未覆盖层压板,建议处理PTFE表面以提供足够的附着力。PTH制备中使用的化学成分也可用于表面处理。建议使用等离子体蚀刻或含有钠的化学试剂。

2.蚀刻PTFE表面具有足够的粗糙度,可用于粘合。如果对薄板进行蚀刻或未覆盖层压板,建议对PTFE表面进行处理,以提供足够的附着。pth制备过程中使用的化学成分也可用于表面处理。建议使用等离子蚀刻或含钠化学品。

The etched PTFE surface has sufficient roughness for bonding. Where the lamella is etched or where the laminate is not covered, it is recommended that the PTFE surface be treated to provide adequate attachment. The chemical components used in the pth preparation process can also be used for surface treatment. Plasma etching or sodium containing chemicals are recommended.

3.铜表面处理应确保最佳结合强度。棕色氧化铜电路处理将加强表面形状,以便于使用tacbond粘合剂进行化学粘合。第一个过程需要清洁剂去除残留物和处理油。接下来,进行细铜蚀刻以形成均匀的粗糙表面区域。棕色氧化物针状晶体在层压过程中,粘合层稳定。像任何化学过程一样,每个步骤后都需要进行充分的清洁。残留的盐会抑制粘附。应监督最终冲洗,并保持pH值小于8.5。逐层干燥,确保表面不被手油污染。

Copper surface treatment should ensure optimum bond strength. The brown copper oxide circuit treatment will reinforce the surface shape for chemical bonding using TacBond adhesive. The first process requires a cleaner to remove residual and processing oil. A fine copper etch is then performed to form a uniform rough surface area. The brown oxide needle crystals stabilize the adhesive layer during lamination. As with any chemical process, adequate cleaning after each step is required. Salt residue will inhibit adhesion. The final rinse should be supervised and maintained at a pH of less than 8.5. Dry layer by layer and ensure that the surface is not contaminated by oil on your hands.

1.在250华氏度(100℃)下烘烤层压板以去除水分。层压板应储存在严格控制的环境中,并在24小时内使用。

Bake the plate at 250oF (100 ° C) to remove moisture. The plies are stored in a tightly controlled environment and used within 24 hours.

2.工具板和第一块电解板之间应使用压力场,以便控制板中的压力能够均匀分布。电路板和待填充电路板中存在的高压区域将被磁场吸收。该场还可以统一从外部到中心的温度。因此,控制板和控制板之间的厚度是均匀的。

A pressure field should be used between the tool plate and the first plate to distribute the pressure in the control panel evenly. The high voltage regions present in the board and in the board to be filled will be absorbed by the field. The field also unifies the temperature from the outside to the center. Thereby forming a uniform thickness between the control board and the control board.

3.电路板必须由供应商提供的TAC-bond薄层组成。切割和堆放薄层时,应注意防止污染。根据电路设计和填充要求,需要1至3层粘合剂薄层。要填充的区域和介电要求用于计算0.0015”(38微米)薄板的需求量。建议在层压板之间使用干净的精制钢或铝镜板。

The board must consist of a thin layer of TAC BOND supplied by the supplier. Be careful to prevent contamination when cutting thin layers and stacking. Depending on the circuit design and filling requirements, 1 to 3 bonded layers are required. The areas that need to be filled and the dielectric requirements are used to calculate the 0.0015" (38 micron) sheet. It is recommended to use clean steel or aluminum mirror plates between the laminates.

4.为辅助层压,加热前抽真空20分钟。在整个循环中保持真空。抽气将有助于确保电路封装完成。

To assist in lamination, vacuum treatment is carried out for 20 minutes before heating. The vacuum is maintained throughout the cycle. Pumping away from the air will help ensure that the circuit is packaged.

5.在中心板的外围区域放置热电偶可以确定温度监控和适当的循环。

Place a thermocouple in the peripheral area of the center plate to determine temperature monitoring and appropriate cycles.

6.板材可装入冷的或预热的压盘中启动。如果不使用压力场进行补偿,热升和循环将不同。进入包装的热量输入不重要,但应尽可能控制,以减少外围和中心区域之间的间隙通常,加热速率在12-20of/min(6-9℃/min)和425of(220℃)之间。

The plate can be loaded onto a cold or preheated press platen. If the pressure field is not used for compensation, the heat rise and cycle will be different. It is not critical to enter heat into the package, but it should be controlled to minimize the gap between the perimeter and the center. Typically, the heat rate is between 12-20oF/min (6-9 °C/min) and 425oF (220 °C).